The Making of a Pantry Staple: Demystifying the Tomato Paste Production Process

Tomato paste – that concentrated burst of umami goodness – is a workhorse in kitchens around the globe. But have you ever stopped to consider how those plump, juicy tomatoes are transformed into the thick, vibrant paste found in that tiny can?

This deep dive into the tomato paste production process takes you behind the scenes, revealing the meticulous journey from vine to factory. Get ready to impress your friends with your newfound knowledge of this culinary essential!

Phase 1: Selecting the Perfect Tomato – It Starts at the Source

Not all tomatoes are created equal, especially when crafting the perfect paste. Paste tomatoes, such as the celebrated Roma and San Marzano varieties, reign supreme. Their firm flesh, low water content, and intensely rich flavor make them ideal for achieving that thick, concentrated paste.

Phase 2: From Field to Factory – Harvesting & Handling

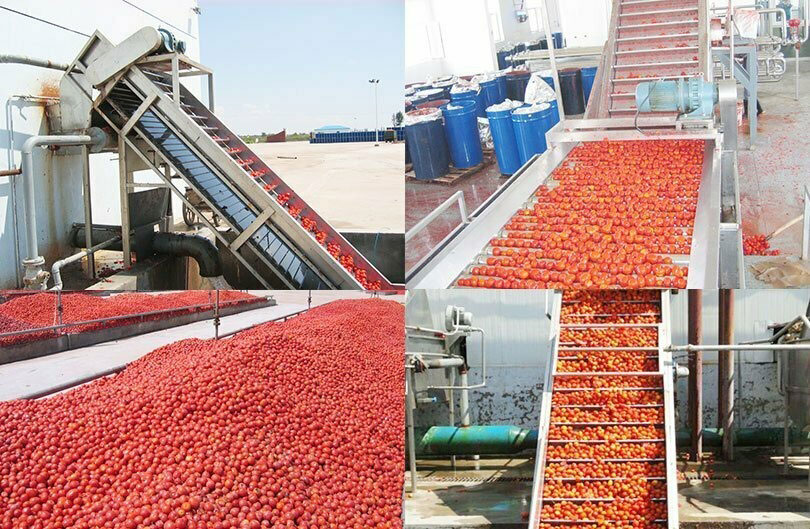

Harvest Time: The journey begins with the harvesting of perfectly ripened tomatoes, often utilizing mechanical methods for large-scale production.

Sorting & Washing: Next comes a critical step – sorting. Skilled workers or automated systems meticulously inspect and separate damaged, unripe, or blemished tomatoes. Only the finest specimens earn a place in the next stage. A thorough washing follows, ensuring only the cleanest tomatoes make the cut.

Phase 3: The Transformation Begins – Crushing, Heating, and Extracting

Crushing: Now, the transformation begins. The sorted tomatoes are crushed to break down their structure and release their precious juices.

Heating: This vital step deactivates enzymes that could negatively impact the paste's color and flavor. Heating also helps soften the tomatoes for the subsequent stage.

Juicing and Seeding: The heated, crushed tomatoes are then passed through a pulper or extractor. This ingenious machine efficiently separates the seeds and skins (often diverted to create other products, like ketchup) from the coveted tomato juice and pulp.

Phase 4: The Heart of the Matter – Concentration

Evaporation: From Juice to Paste: This stage is where the magic truly happens. The tomato juice, brimming with flavor, enters massive vacuum evaporators. These specialized vessels gently simmer the juice under controlled heat and pressure. Slowly and steadily, excess water evaporates, leaving behind a concentrated, thick paste.

Degrees of Concentration: The duration of evaporation determines the final paste's consistency and concentration, resulting in familiar variations:

Tomato Puree: Lightly concentrated, retaining a pourable consistency.

Tomato Paste: Heavily concentrated, yielding the thick, rich paste we know and love.

Tomato Paste Concentrate: The most concentrated form, requiring dilution before use.

Phase 5: Preservation & Packaging – Ensuring Freshness and Longevity

Packaging: The hot, concentrated paste is swiftly packaged into sterilized containers – cans, tubes, aseptic cartons, or drums – depending on the intended use and market demand.

Sterilization: To ensure a shelf-stable product, the filled containers undergo a sterilization process, typically involving heat treatment. This eliminates any lingering microorganisms that could cause spoilage, preserving the paste’s quality and extending its shelf life.

Cooling & Labeling: Post-sterilization, the containers are rapidly cooled to prevent overcooking and preserve flavor. Finally, they're labeled with essential information and prepared for distribution, ready to add a burst of flavor to kitchens around the world.

Modern Marvels: Advancements in Tomato Paste Production

While the fundamental principles of tomato paste production have withstood the test of time, advancements in food technology continue to refine and enhance the process:

Aseptic Processing: This sophisticated technique sterilizes both the tomato paste and its packaging separately before filling. Aseptic processing ensures a longer shelf life, preserves a fresher flavor profile, and often eliminates the need for added preservatives.

Water Recycling: With a growing emphasis on sustainability, many modern facilities have integrated water recycling systems. This eco-conscious approach significantly reduces water consumption, minimizes waste, and lessens the environmental impact of production.

Automated Systems: From sorting and washing to filling and labeling, automation plays a vital role in modern tomato paste production. This not only streamlines operations and boosts efficiency but also ensures consistent quality across batches.

The Tomato Paste Spectrum – Beyond the Basics

Tomato paste isn't a one-size-fits-all ingredient. The market offers several variations, each with unique characteristics:

Double-Concentrated Tomato Paste: This potent paste packs double the concentration of standard tomato paste, delivering a wallop of flavor in a smaller quantity.

Sun-Dried Tomato Paste: Crafted from tomatoes traditionally dried under the Mediterranean sun, this variety boasts a distinctively intense, concentrated flavor with a hint of sweetness.

The next time you reach for that familiar can or tube of tomato paste, pause for a moment to appreciate the meticulous journey it took from the vine to your kitchen. It's a testament to ingenuity, culinary tradition, and the humble tomato's remarkable versatility.

Must-Read Blogs For Chain Restaurants Owner

Sausage Stuffer Machine

Sausage Stuffer Machine Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Poultry Feather Removal Machine

Poultry Feather Removal Machine

Ready to Get Started?